Gator Ukulele

This University of Florida gator-themed pineapple-concert ukulele began as a personal project (see below). As my Honors Thesis in my senior year of university, I continued this project with the goals to (1) re-design the ukulele to fix the deformation issue in my prototype, (2) 3D print the neck and head in addition to the body, and (3) manufacture the ukulele in 3 different materials (PLA, wood-filled PLA, and stainless steel-filled PLA) to compare timbres. A complete write-up of my thesis including my process and findings can be found HERE.

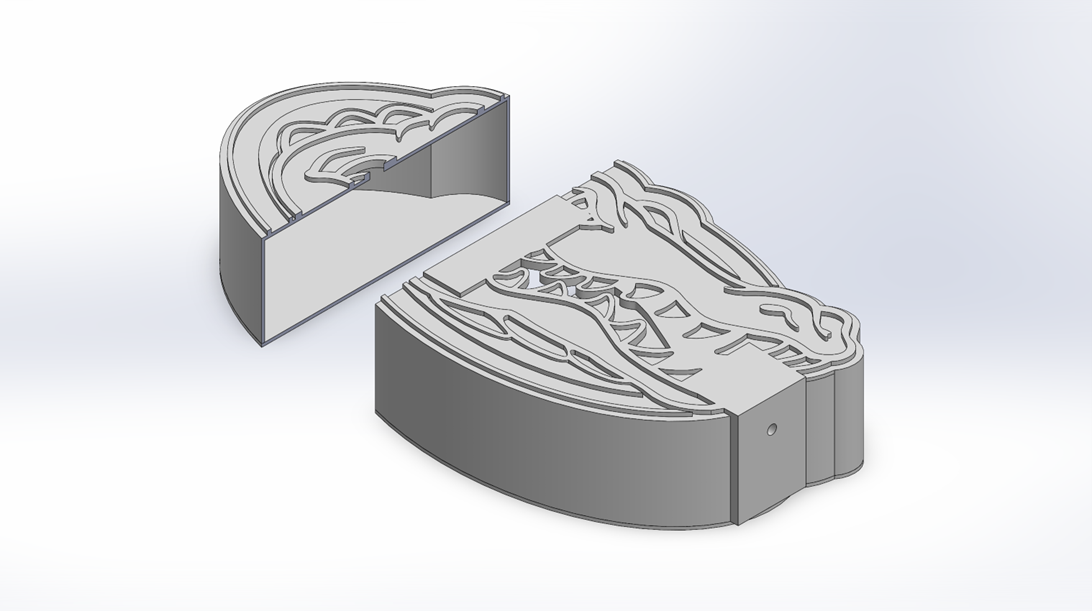

To accomplish the first goal, I performed bending and buckling calculations on the neck, body, and head after approximating them as beams, confirming that the current designs for the neck and head were sufficient to 3D print instead of purchasing stock (accomplishing goal 2) and that the body's top thickness should be increased to prevent buckling. After adding braces to the body, I performed a finite element analysis simulation on simplified models of the neck and body to support my findings. I then manufactured the 3 instruments.

Gator Ukulele

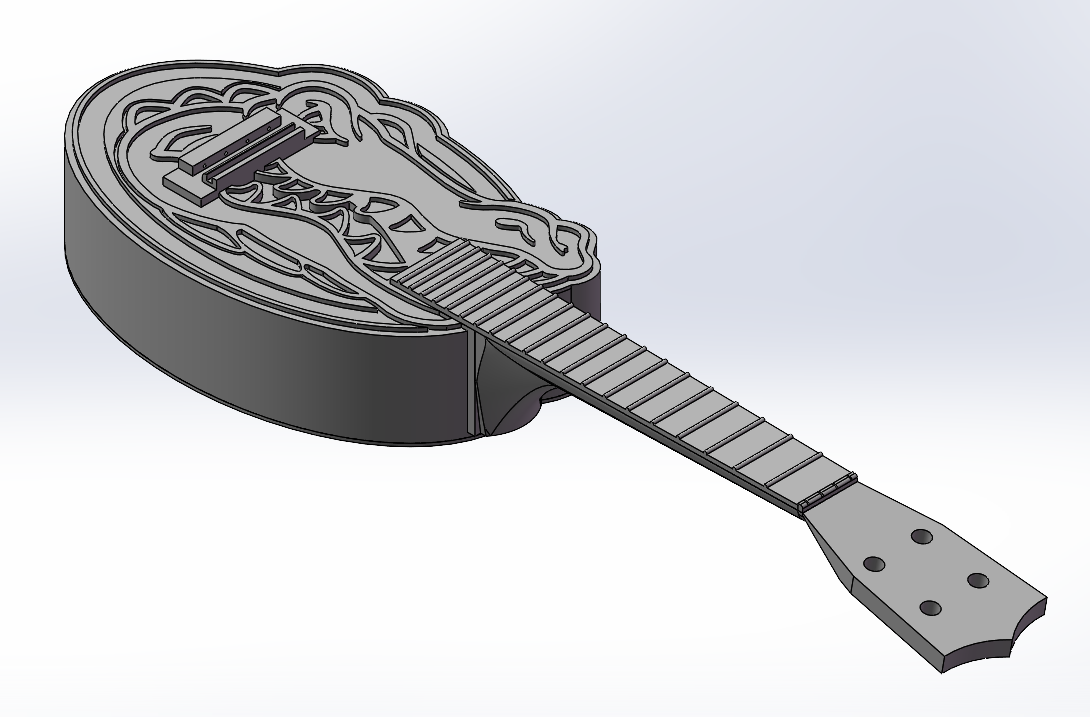

This University of Florida gator-themed pineapple-concert ukulele was created as a personal project to use my CAD skills to combine mechanical design and creative design. The dimensions of the ukulele are based on the Oaktown Strings concert pineapple ukulele.

As a concert ukulele, the body was designed with a 15-inch scale length (the distance from the top of the neck to the bridge on the bottom half of the body). To incorporate the gator theming, the tongue of the University of Florida Gators logo was used as the sound hole, replacing the usual circular sound hole. Since the ukulele was to be 3D printed out of PLA as opposed to manufactured out of wood, braces were omitted within the design of the body to reduce stiffness, improving sound resonance.

In version 1 of the ukulele, the neck assembly (neck, fretboard, and nut) was to be 3D printed as one part and the body included a connected bridge. The body was to be 3D printed in two parts: the top and sides as one part and the back as another part.

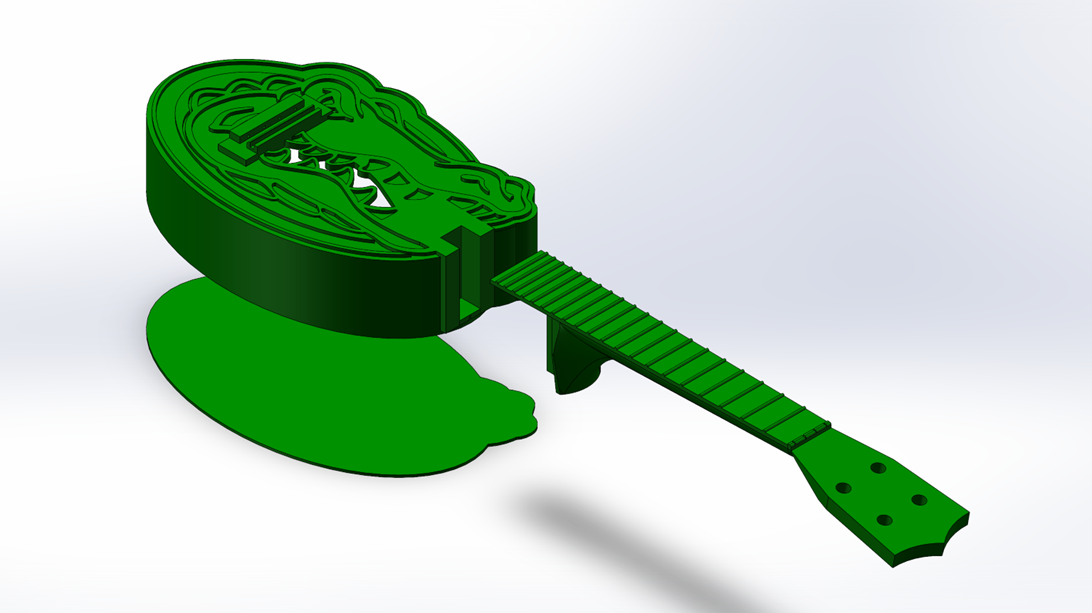

In version 2 (the first version to be physically manufactured and prototyped), modifications were made to decrease manufacturing time. This included buying a stock bridge and neck assembly to attach to the 3D printed body. To fit on a 250mm x 250mm 3D printer bed, the body was split into a different set of two parts: one part from the bridge up to the neck and one part from below the bridge to the bottom of the ukulele. The pieces of the body were then 3D printed and assembled with the stock parts.

I later continued this project as my Honors Thesis (see above).