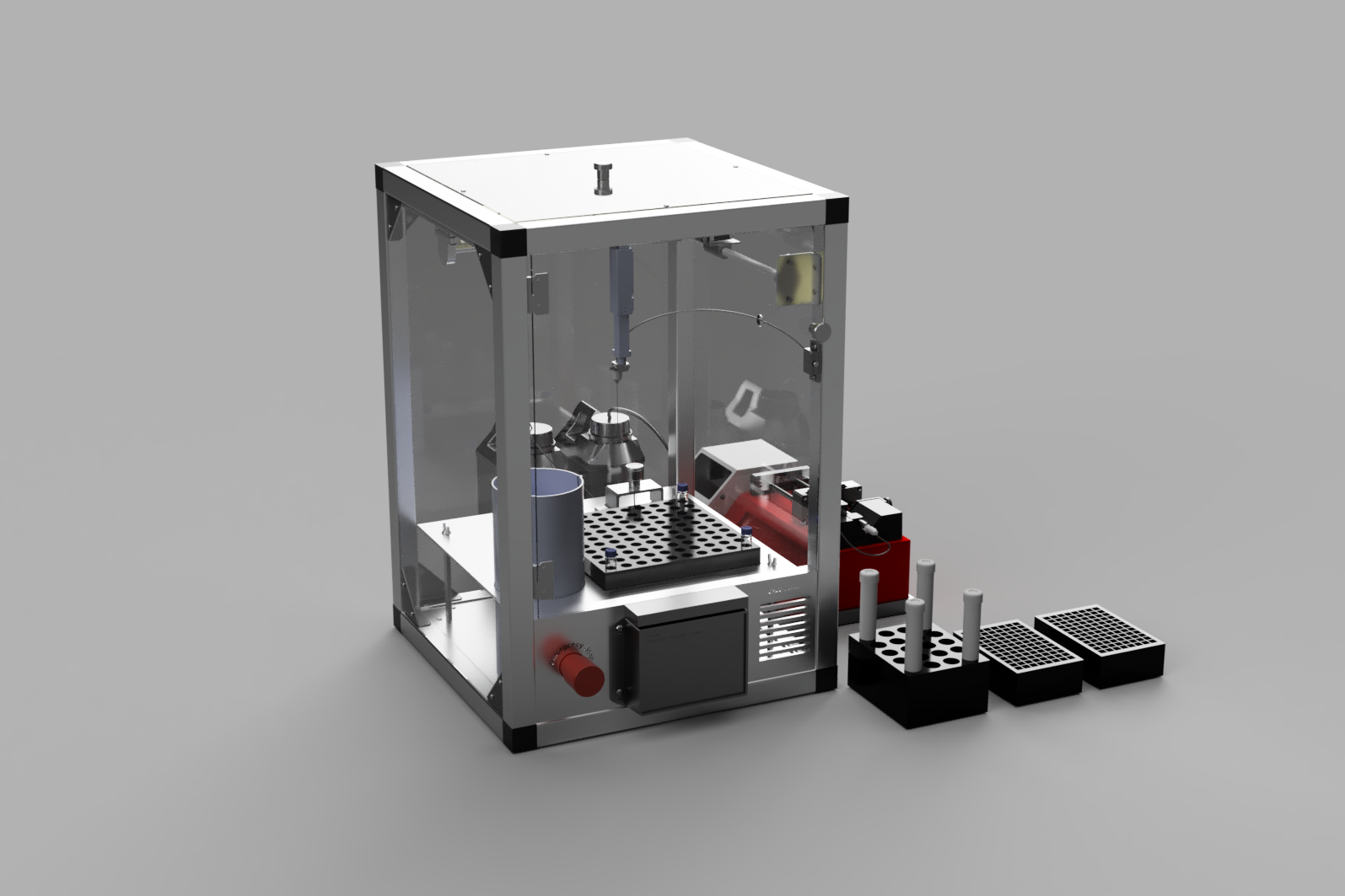

Biofluid Autosampler System

As part of my senior capstone coursework, I led a team of 10 mechanical engineers to design a lower cost biofluid autosampler with a temperature controlled enclosure that is able to be manufactured and assembled by a research lab and is comparable to similar on-the-market devices.

During the first phases of the project, I led the team in researching prior solutions and ideating potential designs for our solution. Once detailed design began, I worked on the fluid subsystem to ensure that the autosampler met sample size, volumetric accuracy, and sampling speed constraints for the client. This included selecting a push-to-fill fluid delivery system which comprised of a peristaltic pump, syringe pump, and 6-port injection valve that allowed delivery in 17.7 seconds for a 0.5 μL volume (the minimum volume requested by our client) and 90.5 seconds for a 500 μL volume (the maximum volume requested by our client). The precision of our system varied with sample size. After discussions with the client to ensure all other constraints, namely cost constraints, were met, it was deemed acceptable that our system met precision requirements for all sample volumes less than an estimated 487 μL (97.4% of sample volumes requested by the client). Further details on our constraints and how they were met for the fluids subsystem can be found on pg. 59-61 of our final design report found below.

As the teams continued designing, I ensured all systems would be well integrated with each other by encouraging inter-subteam communication and completed the final assembly and animation of the systems in CAD to validate our design. Our final design report can be found HERE.